The UV LED curing system offers numerous benefits, including superior energy efficiency, accelerated cure speeds, precise process control, enhanced safety measures, minimized maintenance needs, and decreased operational costs. These advantages make it a top choice for a wide range of applications across diverse industries.

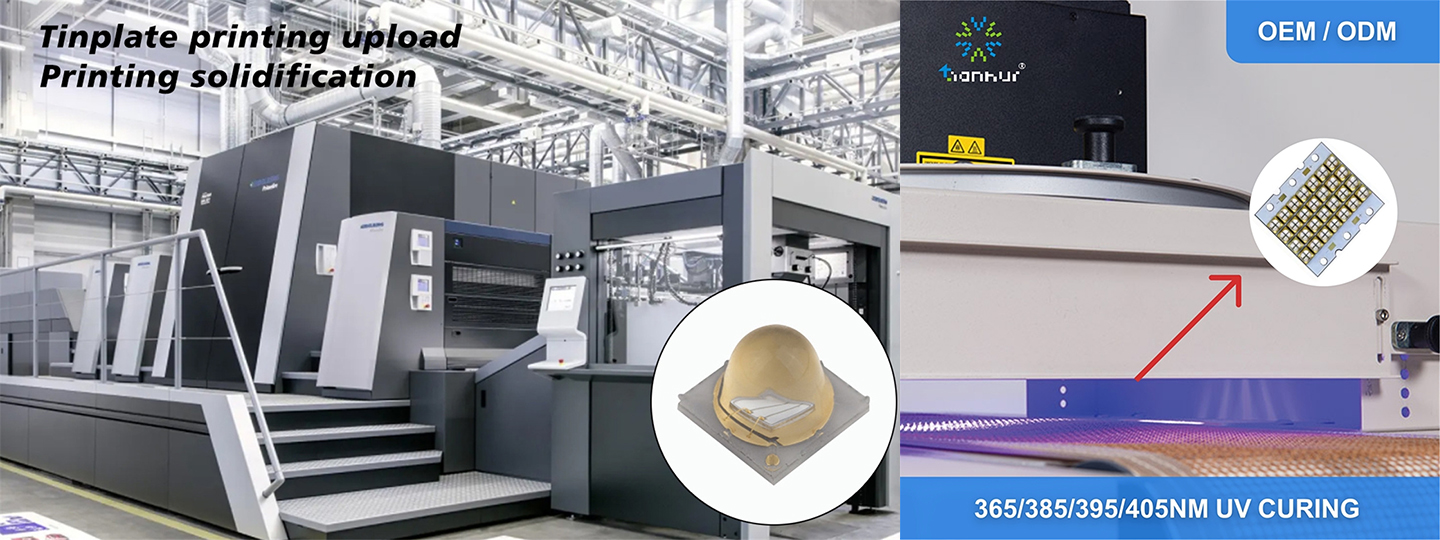

In the printing industry, UV curing systems have become a must-have. They are particularly useful in processes like offset, flexographic, and digital printing. The system's ability to cure instantly allows for high-speed production and ensures high-quality prints on various substrates.

The coating and finishing industries, such as wood and furniture manufacturing, also reap the benefits of UV LED curing systems. They enable the rapid curing of coatings and finishes, leading to efficient production processes and excellent surface treatments.

Moreover, UV LED technology plays a pivotal role in adhesive bonding applications across various sectors, including electronics and medical devices. The controlled and speedy curing process guarantees robust and reliable bonds.

With these remarkable benefits, the UV LED curing system is poised to revolutionize numerous industries, driving efficiency, quality, and productivity to new heights.

3D Printing: UV LED curing systems play a crucial role in 3D printing technologies that utilize UV-curable resins. The precision and control provided by UV LED technology enable the creation of intricate and detailed 3D-printed structures with remarkable accuracy.

Electronics Manufacturing: In the electronics manufacturing sector, UV LED curing systems are essential for curing adhesives, encapsulants, and coatings. The low heat emission during the curing process protects sensitive electronic components, ensuring their integrity and reliability.

Medical Devices: UV LED curing technology, powered by UV LED diodes, finds its application in the production of medical devices. It is used for bonding, sealing, and coating applications, ensuring reliability and sterility due to the instant curing process.

Automotive Finishing: The automotive industry also benefits from UV curing systems, particularly in printing applications. These systems are employed for curing coatings on various components, contributing to the efficiency of manufacturing processes and delivering high-quality finishes that enhance the aesthetics and durability of automotive products.

With its superior energy efficiency, accelerated cure speeds, precise process control, and safety features, the UV LED curing system continues to revolutionize numerous industries, driving efficiency, quality, and productivity to new heights.